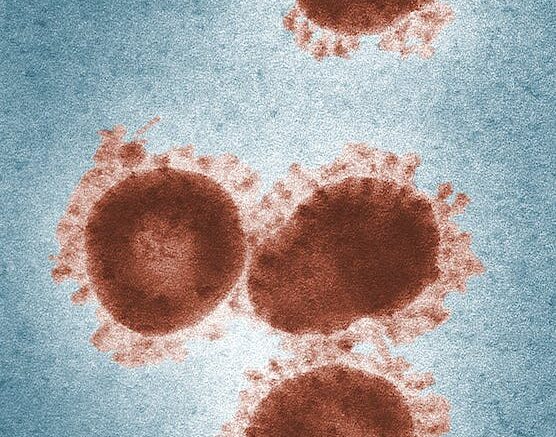

Viral vector manufacturing is a critical process in the development of innovative gene therapies and vaccines. By leveraging the natural ability of viruses to transport their genomes inside the cells they infect, viral vectors are designed to deliver therapeutic genes or vaccine antigens to target cells. As the demand for gene therapies and vaccines continues to grow, understanding the history, design, manufacturing, and applications of viral vectors becomes increasingly important.

What is a Viral Vector?

Viral vectors are tools designed to deliver genetic material into cells, leveraging the natural ability of viruses to transport their genomes inside the cells they infect. These modified viruses are used in gene therapy and vaccine development to protect the new gene from degradation while delivering it to the target cells.

History of Viral Vectors

The concept of viral vectors dates to 1972 when the first recombinant DNA was created from the SV40 virus through genetic engineering. Since then, various types of viral vectors have been developed, including retroviral vectors, adenoviral vectors, and lentiviral vectors. These vectors have been used in numerous research studies and clinical trials, paving the way for innovative therapies and vaccines.

How is a Viral Vector Designed?

The design of a viral vector depends on several factors, such as the desired level of gene expression, target cell type, and safety considerations. Typically, a viral vector is engineered to carry the therapeutic gene or vaccine antigen while removing or inactivating any harmful viral genes. This ensures that the vector can efficiently deliver the genetic material without causing disease or adverse effects.

How to Manufacture the Viral Vector

Viral vector manufacturing involves several steps, including cell line development, vector construction, transfection, purification, and quality control. The process starts with establishing a suitable cell line for viral vector production. Next, the viral vector is designed and constructed to carry the therapeutic gene or vaccine antigen. This is followed by introducing the viral vector into the production cell line through a process called transfection. Afterward, the viral vector is isolated from the production cell line and purified to remove impurities. Finally, quality control measures are put in place to ensure the purity, potency, and safety of the viral vector.

Applications of Viral Vectors

Viral vectors have a wide range of applications in gene therapy and vaccine development. They have been used to treat various diseases, including metabolic, cardiovascular, muscular, hematologic, ophthalmologic, and infectious diseases, as well as cancer. Some examples of viral vector-based therapies include chimeric antigen receptor (CAR) T-cell therapies for cancer treatment and gene therapies for inherited disorders like primary immunodeficiencies and hemoglobinopathies.

Interesting Facts about Viral Vectors

- The first viral vector was introduced in 1972 through genetic engineering of the SV40 virus.

- Retroviral vectors, adenoviral vectors, and lentiviral vectors are among the most commonly used viral vectors in gene therapy and vaccine development.

- Viral vector-based therapies, such as CAR T-cell therapies, have demonstrated remarkable clinical success in patients with B-cell malignancies, leading to regulatory approval of the first genetically engineered cellular therapy.

- The development of non-viral, synthetic vectors is an area of ongoing research, with the potential to overcome some limitations of viral vectors.

Shortly, viral vector manufacturing is an essential component in the development of innovative therapies and vaccines. As the demand for gene therapies and vaccines continues to grow, advances in viral vector manufacturing technology and the exploration of new applications will be crucial to meeting the needs of patients and the healthcare industry.