Laboratory testing plays a pivotal role in modern healthcare, research, and various scientific endeavors. Each year, an astonishing 14 billion laboratory tests are ordered in the U.S. only, shaping critical decisions in patient diagnosis, treatment, and disease management. However, the success and influence of these tests are deeply dependent on the precision and trustworthiness of their outcomes. For the advancement of precision medicine and science, it’s crucial that lab experiments uphold the highest standards of accuracy and validity.

Even with an increased focus on quality control in labs, mistakes can happen, jeopardizing the credibility of experimental results. Such mistakes might arise from human oversight, equipment failures, deviations in procedures, or inferior materials. The repercussions of these errors can be significant, resulting in incorrect diagnoses, flawed research findings, and squandering of precious resources.

In this post, we’ll delve into five essential steps that laboratories can implement to minimize errors effectively. By following these guidelines, researchers can enhance the reliability and reproducibility of their experiments, leading to more trustworthy scientific discoveries and improved patient care.

Invest in High-Quality Equipment and Materials

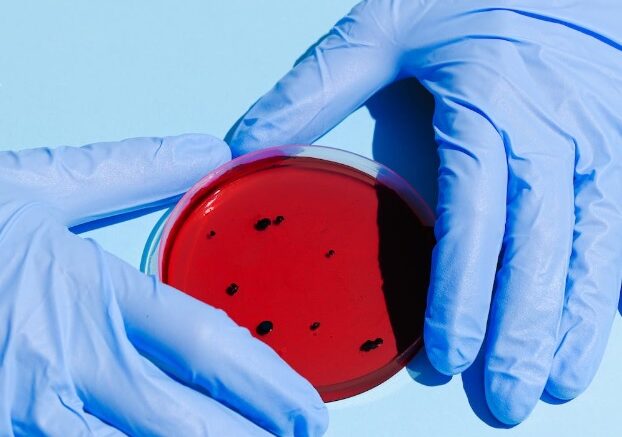

The foundation of any successful laboratory experiment lies in the quality of equipment and materials used. Skimping on these essentials can lead to inaccurate data and compromised results. Putting funds into cutting-edge equipment guarantees not just accurate readings but also conserves time and energy.

One such crucial piece of equipment in the realm of immunoassays is the ELISA plate washer. This device plays a vital role in washing and handling microplates, which are commonly used in ELISA experiments. By automating the washing process, ELISA plate washers eliminate human errors and variations that may occur during manual washing. Moreover, they enable thorough washing, minimizing the risk of cross-contamination between wells, which could lead to false positives or false negatives.

Additionally, proper calibration and maintenance of equipment are essential to avoid systematic errors that may occur due to drifts or inaccuracies in measurements. Using reputable suppliers for materials such as reagents, chemicals, and consumables is essential for the consistency and validity of experimental outcomes. By prioritizing the acquisition of reliable equipment and materials, laboratories set a solid foundation for producing dependable and reproducible results.

Standardize Protocols and Procedures

In a laboratory setting, consistency is key. Standardizing protocols and procedures is essential to ensure that experiments are conducted in the same manner every time. Deviating from established protocols can introduce variability and result in erroneous data.

Creating and documenting standardized protocols not only reduces errors but also aids in reproducing experiments successfully. By providing clear and detailed instructions, researchers can avoid confusion and foster better collaboration among team members. Moreover, if any issues arise during an experiment, having a standardized protocol in place can help identify the source of the problem and rectify it promptly.

Train and Educate Lab Personnel

No matter how advanced the equipment is, its potential can only be fully realized with skilled and knowledgeable lab personnel. Training and educating the staff is crucial to ensure that they understand the procedures thoroughly and are aware of the best practices.

Regular training sessions help keep lab personnel updated with the latest techniques and methodologies. Additionally, it fosters a culture of continuous improvement and emphasizes the significance of attention to detail. When team members are well-trained, they can identify potential errors and take corrective actions before they escalate, saving time and resources.

Perform Regular Maintenance and Calibration

Laboratory equipment requires proper care and maintenance to function optimally. Regular maintenance ensures that instruments are in top condition, reducing the risk of malfunctions and inaccuracies. Calibration is another crucial aspect of ensuring the accuracy of the equipment.

Developing a comprehensive maintenance schedule for various lab instruments is essential. This schedule should include routine inspections, cleaning, and necessary repairs. Regular calibration of equipment, such as pipettes, balances, and spectrophotometers, guarantees that measurements are accurate and consistent over time.

Implement Quality Control Measures

In a laboratory, quality control measures act as the last line of defense against errors. They help identify issues during experiments, providing an opportunity to rectify them before they affect the final results. Without quality control, even a minor mistake can lead to significant consequences.

Implementing quality control involves incorporating standards, controls, and replicates in experiments. It also includes the careful validation and verification of data. By doing so, researchers can ensure that their results are reliable and can be trusted by the scientific community.

Final Thoughts

Achieving precise and dependable data is fundamental for scientific progress. Minimizing lab errors through quality equipment, standardized protocols, and well-trained personnel is paramount. Regular maintenance, calibration, and the implementation of quality control ensure the credibility of results. By embracing these five crucial steps, researchers pave the way for groundbreaking discoveries with unwavering accuracy, making a lasting impact in the pursuit of knowledge.